Client: Chemical Plant in Hokuriku Region

Application: Sludge Recovery from Hydrochloric Acid-Containing Solution

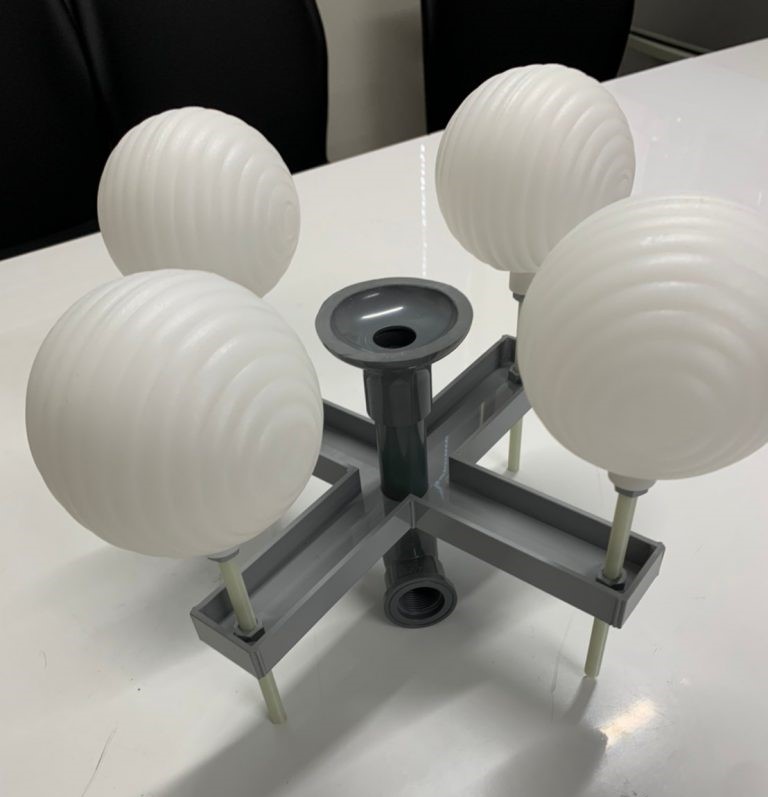

Model: Resin Recovery Float

Sludge recovery from solutions containing hydrochloric acid

A major chemical plant in the Hokuriku region requested sludge recovery from a solution containing hydrochloric acid.

Although the acid concentration was low, metals like SUS commonly used for standard recovery floats were unsuitable.

Therefore, we proposed and supplied a fully custom resin recovery float, which was adopted.

Water level adjustment bolts and all parts are resin

The biggest challenge was ensuring strength and selecting suitable materials for the necessary bolts.

We enhanced strength by using multiple PVC bend welds and increased the thickness of resin bolts.

This corrosion-resistant recovery float, rare in the market, was custom-made by our expert team and successfully delivered.

For recovery challenges, please consult H2!

As in this case, we also specialize in custom-made products beyond our standard model lineup.

Please feel free to contact us for inquiries for this case.

【浮上油回収ろ過の専門サイトはこちら】