> High discharge accuracy of ±1%, easy maintenance

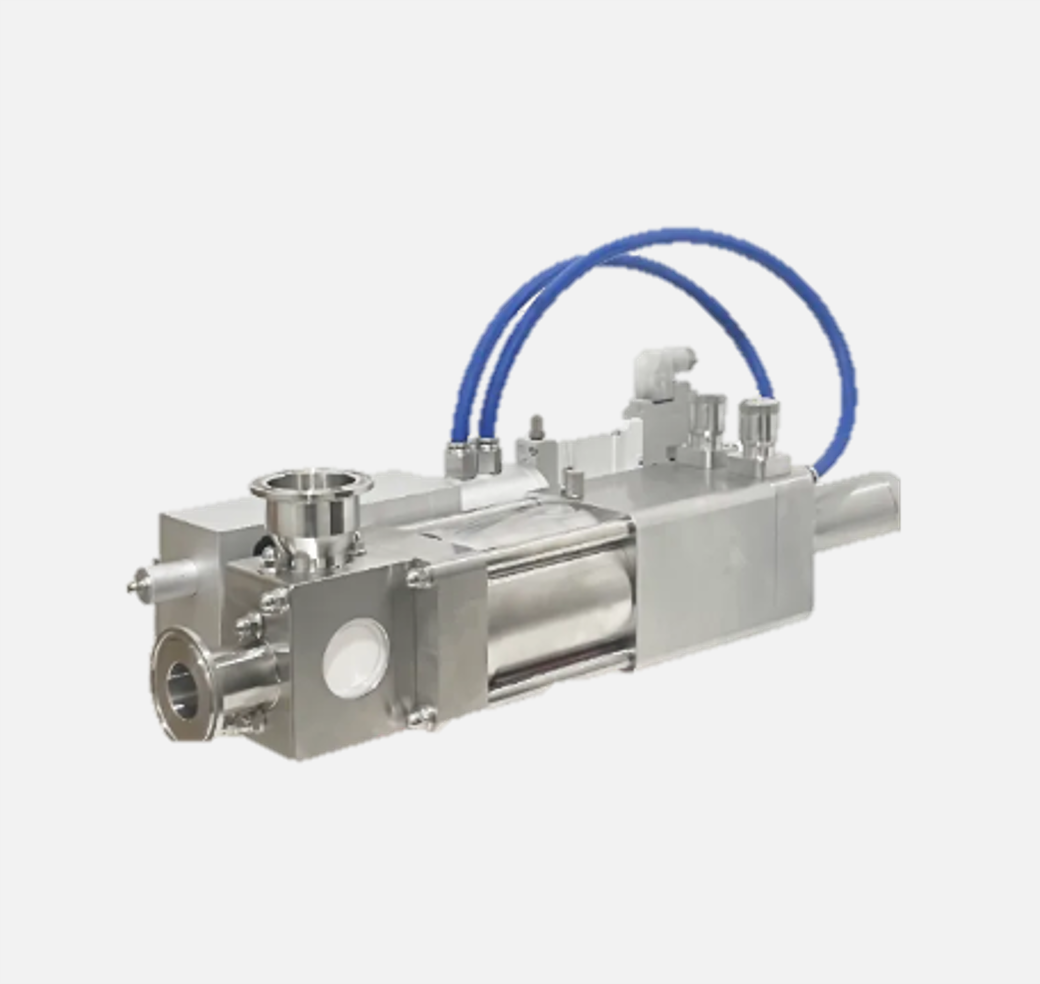

Sanitary Plunger Pump

This high-precision plunger pump is ideal for metered liquid filling and coating. Its ±1% discharge accuracy is supported by reliable Japan-made components. Delivery time is approximately 45 days, significantly shorter than previous models.

プランジャーポンプ移送動画

味噌・ハチミツ・化粧ジェルなど、実際の移送をご覧いただけます。

> Sanitary Plunger Pump HPL Series ー Key Features

This sanitary plunger pump is ideal for dispensing food, cosmetics, adhesives, and similar products.

While sanitary plunger pumps typically require about three months for delivery, we have shortened the lead time significantly to 45 days. Made in Japan and designed for use close to production processes, this model offers both reliability and short delivery time.

Short lead time

- Guaranteed delivery within 45 days after order

- Consumables and parts are always in stock

High precision, ideal for filling and coating

- Reliable Japan-made quality with high precision

- Suction and discharge speeds can be adjusted independently

Wide range of options

- Drip-prevention nozzle

- Dedicated controller

Catalog Download & Inquiries

Sanitary Plunger Pump HPL Series ー Specifications & Lineup

Main Applications

■Low Viscosity: oil, lubricants, alcohol, dressings, seasoning liquids, edible oils, soups, soy sauce, juices, shampoo, conditioner, sulfuric acid, electrolytes, chemicals, etc.

■High Viscosity: Honey, jam, ketchup, syrup, starch syrup, sweet bean paste, cosmetic cream, ointment, emulsion, pigment, adhesive, UV resin, ink, grease, whipped cream, carbonated beverages, pastry dough, polymer solutions, emulsions, latex, and more.

Product Specifications

| Discharge Volume Range | ~2,000cc/shot |

| Main Materials | Casing/SUS316 |

| Plunger/SUS316, zirconia ceramics | |

| Plunger seal/PTFE, UHMW | |

| O-ring/EPDM, FKM, silicone, FFKM | |

| Air-driven system | Air drive system |

| Liquid Temperature Range | 5〜90°C |

| Transferable Viscosity Range | Up to approximately 80,000 mPa·s |

Product Lineup

■C Series / Transfer viscosity up to 5,000 mPa·s

| Model | Maximum Discharge Volume | Stroke Speed | Air Consumption | Outer Dimensions | Weight | Connection Port Size | ||

| CC | cycle/min | ℓ/min | Total length (mm) | Width (mm) | Kg | Suction Side | Discharge Side | |

| HPL1C0002 | ~0.2 | 150 | 12.5 | 205.0 | 45 | 2.5 | Rc1/4 | Rc1/4 |

| HPL1C0006 | ~0.6 | |||||||

| HPL1C0025 | ~2.5 | Rc3/8 | Rc1/4 | |||||

| HPL2C007 | ~7.0 | 120 | 23.5 | 268.0 | 52 | 3.2 | Rc1/2 | Rc3/8 |

| HPL2C014 | ~14.5 | |||||||

| HPL2C020 | ~20.0 | |||||||

| HPL4C058 | ~58.0 | 150 | 51.0 | 263.2 | 75 | 6.8 | Rc1 | Rc1 |

| HPL4C116 | ~116.0 | 120 | 85.0 | 339.4 | 7.6 | |||

| HPL4C174 | ~174.0 | 90 | 102.0 | 416.2 | 8.3 | |||

■R Series / Transfer Viscosity 5,000 mPa·s or Higher

| Model | Maximum Discharge Volume | Stroke Speed | Air Consumption | Outer Dimensions | Weight | Connection Port Size | ||

| CC | cycle/min | ℓ/min | Total Length (mm) | Width(mm) | Kg | Suction Side | Discharge Side | |

| HPLR10002 | ~0.2 | 80 | 12.5 | 247.0 | 87.2 | 3.3 | 1.0S | 1.0S |

| HPL1R0006 | ~0.6 | |||||||

| HPL1R0025 | ~2.5 | |||||||

| HPL2R007 | ~7.0 | 60 | 23.5 | 293.3 | 94.2 | 4.2 | 1.5S | |

| HPL2R014 | ~14.5 | |||||||

| HPL2R020 | ~20.0 | |||||||

| HPL4R058 | ~58.0 | 150 | 51.0 | 338.6 | 130.9 | 8.8 | ||

| HPL4R116 | ~116.0 | 120 | 85.0 | 414.8 | 9.5 | |||

| HPL4R174 | ~174.0 | 90 | 102.0 | 491.0 | 10.3 | |||

Option Details

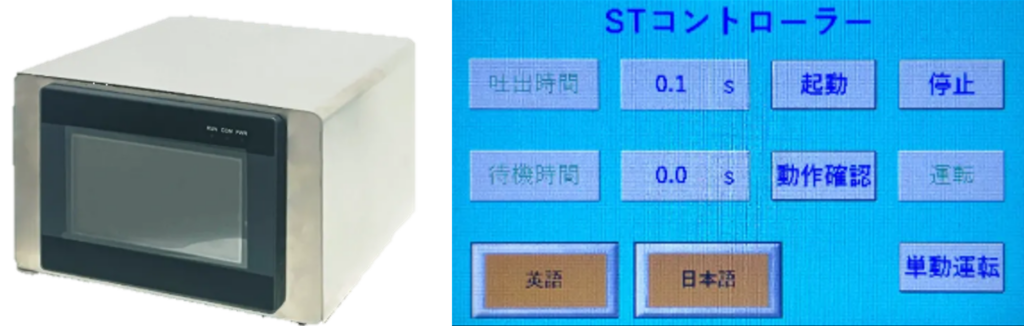

■Plunger Pump Dedicated Controller ST500

・Touch Panel Function

・Discharge time and standby time can be set

・Includes foot switch

■Drip-proof nozzle

・Achieves complete liquid drainage

・Easy to disassemble and clean

・Wide product lineup available

・Precise stroke adjustment possible to match pump operation

Frequently Asked Questions (FAQs)

- Is it possible to replace an existing plunger pump?

-

Yes, it is possible. Please provide the existing manufacturer’s name and model number.

- Is repair service available?

-

Yes, we offer repair services. Please send the unit to us, and we will provide a quotation.

- Are there any charges if I choose not to proceed with the repair?

-

No charges will be incurred if no repair is carried out. There will be no disposal or inspection fees either.

- Does the pump have consumable parts?

-

Packing parts are considered consumables. These items are also available for individual purchase.