>Integrated recovery and separation in a single unit. No test run required

Floating Oil & Debris Recovery Unit with Separator

Place the attached float in the tank – the built-in self-priming pump draws in the fluid, which is automatically separated and recovered by the separation tank. Recovery and separation are completed in one compact unit.

> Floating Oil & Debris Recovery Unit with Separator – Features

The float developed for the recovery skimmer efficiently suctions floating debris on the water surface.

Installed in the pit, it prevents leaks unlike land-based pumps. The integrated float and pump enable recovery and transfer in one unit. The pump is made of corrosion-resistant resin and SUS stainless steel.

No electrical work required – easy installation

- Operates simply by connecting to air supply

- Customizable design to fit installation space

Self-priming design allows dry running

- Equipped with our in-house diaphragm pump

- Self-priming and capable of dry running

Handles challenging fluids with ease

- All SUS construction (for high-temperature fluids)

- PVC/PTFE construction (for corrosive fluids)

Catalogs Download & Inquiries

Floating Oil & Debris Recovery Unit with Separator – ADB Series – Features

Main Applications:

■ Recovery and separation of floating oil in coolant pits

■ Recovery and separation of scum and floating matter in wastewater treatment systems

■ Recovery and separation of sludge and debris in chemical tanks

■ Recovery and separation in confined spaces

Unit Specifications

| Model | ADB-15 |

| External Dimensions | 500W×750H×200D ※ |

| Separator Tank Dimensions | 270W×300H×200D |

| Installation Dimensions | 600W×800H×200D |

| Recovery Pump | Air Diaphragm Pump ADD-15-PP-TPT |

| Supply Air Pressure | Approx. 0.3–0.4 MPa |

| Connection | Suction Hose:φ9×φ13 Return Hose Size:φ15 |

| Floating Material Outlet: 40A(VP40) Air Connection Port:φ10 Quick-Connect Fitting |

Available Options

| Y-Type Strainer | Material Modification | Size Modification |

| Coarse debris and sludge can be collected on the primary side | All SUS construction for high-temperature fluids; resin materials can be customized for corrosive fluids. | Custom sizes available to fit any space. |

Unit Details

Introduction to each part of the unit.

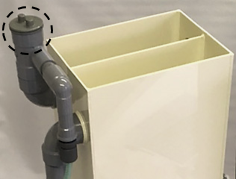

▶ Return Valve

The discharge amount of floating material is adjusted by controlling the liquid level in the separator tank.

Start operation with the valve fully open. If, after sufficient accumulation of floating material, the liquid level does not reach the height of the floating material outlet, gradually close the valve to raise the liquid level.

▶ Inspection Port

Allows inspection of contamination inside the piping.

Although constant fluid flow prevents clogging, this port allows you to check overall contamination levels as a reference.

▶ Discharge Port (VP40A)

Only floating material is discharged due to the liquid level difference in the separator tank.

The system is designed to discharge directly into a pail or similar container, but piping can be connected as needed to suit your setup.

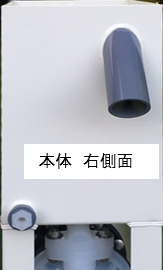

▶ Air Connection Port (Ø10)

A three-way valve is used for the air connection of this unit, designed to release internal pump pressure when stopped.

Since air-operated pumps require a momentarily high starting pressure during startup, always use a three-way valve for turning the pump ON/OFF.

If the pump fails to restart reliably, it may be due to insufficient starting pressure. In such cases, please increase the supply pressure accordingly.

▶ Floating Material Recovery Skimmer

The skimmer draws in floating material while maintaining a constant liquid level using a float ball.

If large chips or debris are sucked in, they will accumulate inside, please inspect and clean as needed.

Do not glue or fix the threaded section between the hose nipple and the unit; allow it to remain loose to ensure proper operation.

Floating Oil & Debris Recovery Unit with Separator – ADB Series|Case Studies

Frequently Asked Questions (FAQs)

- Is an explosion-proof version available?

-

The unit is powered solely by air, making it suitable for use in explosion-proof (hazardous) areas.

- Is repair service available?

-

Yes, we offer repair services. Please send the unit to us, and we will provide a quotation.

- Are there any charges if I choose not to proceed with the repair?

-

No charges will be incurred if no repair is carried out. There will be no disposal or inspection fees either.

- Are replacement parts available?

-

Yes, replacement parts are available. Please contact us for more details.

- Do you have a demo unit available?

-

A demo unit is available. Please contact us for more information.

- Do you offer the float for sale individually?

-

Yes, it is possible. Please contact us for more details.