Just pull the lever

to discharge sludge

after removal

High Magnetic Force Magnet Filter

Filter with high-power 4200G magnet

An inline magnetic filter with high magnetic force that collects iron-based sludge (from cutting, grinding, and cleaning) in both water- and oil-based coolants.

It requires no power supply and has minimal risk of mechanical failure or wear. Thanks to its high magnetic force, sludge that is highly susceptible to magnets (such as iron powder and iron chips) rarely detaches to the downstream side, even at your operating flow rates.

Collected sludge can be easily demagnetized and discharged simply by lifting the handle.

Demagnetization Possible Without Disassembly

The high magnetic force magnet installed inside powerfully captures magnetic sludge.

The captured magnetic sludge adheres to the internal element.

By simply pulling up the demagnetization lever regularly, the magnetic sludge inside can be demagnetized all at once. The demagnetization lever can be operated while the unit is installed on the piping, allowing sludge discharge without the hassle of disassembly.

The demagnetized sludge can be released outside by opening the sludge discharge valve.

See How It Works|High Magnetic Force Magnet Filter

Contact Us

Feel free to reach out for a quote or any questions

High Magnetic Force Filter ー Typical Applications

■Removal of magnetic sludge in oil-based and water-soluble oils

■Removal of magnetic sludge contained in oil-based oils from iron-based grinding, honing, and rolling processes, as well as in oil-based and water-soluble oils from iron-based and cast iron cutting processes

■Removal of magnetic sludge contained in cleaning fluids used in iron-based and cast metal parts washing processes

■Removal of magnetic sludge from industrial water and water containing iron

■Pre-treatment to reduce the load on filtration equipment handling liquids containing magnetic sludge

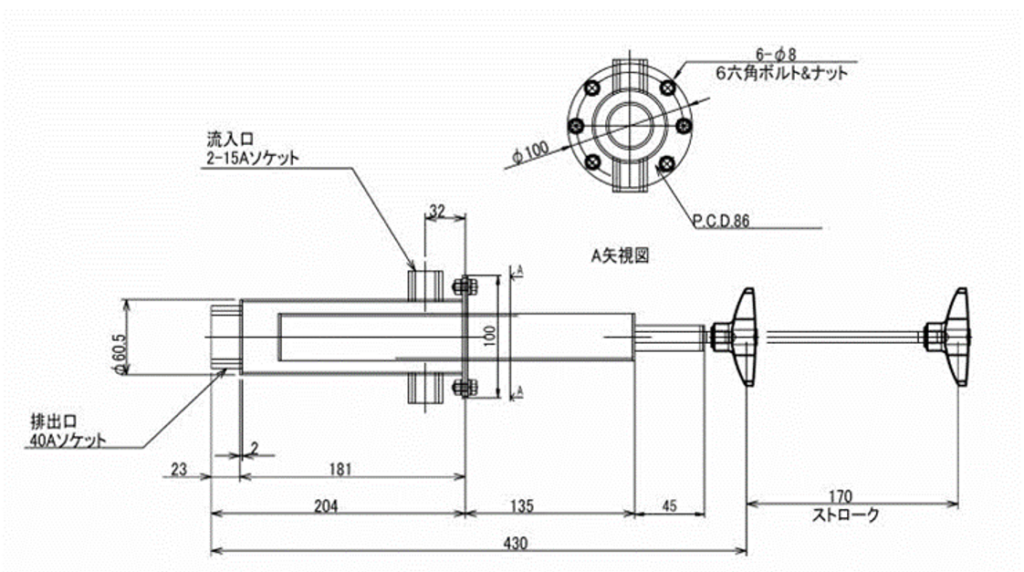

High Magnetic Force Magnet Filter ー Specifications

Important Notes

Sludge that is less affected by magnetic force may leak to the downstream side.

In addition, if too much sludge accumulates, it may cause clogging. Sludge that is not directly attached to the sides of the high-power magnet is more likely to detach and leak downstream.

For applications where leakage to the downstream side is unacceptable, we recommend adding a protective filter housing on the downstream side for two-stage filtration.

Please note that sludge may also leak downstream during demagnetization. We recommend installing a ball valve on the downstream side and closing the valve during demagnetization to prevent leakage.

How to Use

Internal structure

Frequently Asked Questions (FAQs)

- Do you have a demo unit?

-

Yes, we offer demo units upon request. Contact us for details.

- Do you offer filter options for the primary or secondary side?

-

Yes, we do. Please contact us for details.

- Is a power supply required for installation?

-

No power supply is needed. Simply install it on the piping line to remove sludge.

- Can testing be done by sending wastewater?

-

Yes, we can test it at our factory using a wastewater sample you provide.