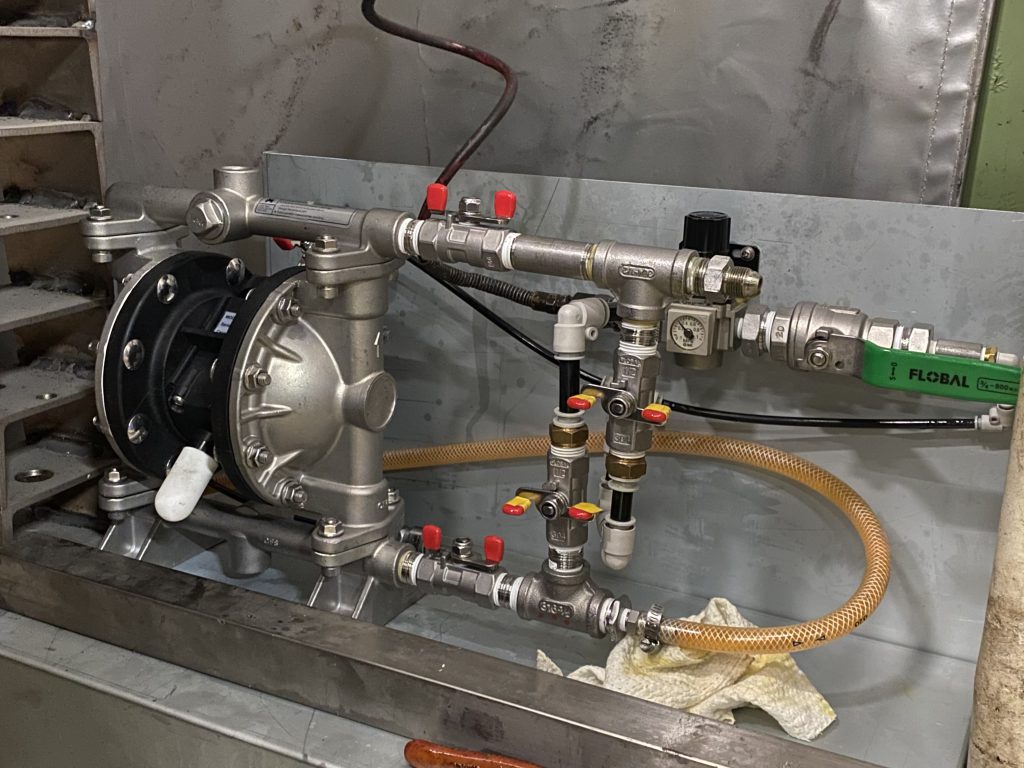

Client: Paint Manufacturer

Application: Horizontal transfer and pressurized delivery of high-viscosity paint from pump

Model: ADD-15-SS (Air Diaphragm Pump)

Horizontal suction of 10,000 cP paint over 3 meters

A major paint manufacturer consulted us about transferring high-viscosity liquid from a mixing tank.

- The paint had a viscosity of approximately 10,000 cP

- Required 3 meters of horizontal self-priming from the tank

- Followed by transfer to the production line

Based on these conditions, we proposed the ADD Series Air Diaphragm Pump.

After delivery, we received a call: “It’s not sucking!”

After delivery, the customer reported, “It’s not sucking!”

We checked fluid specs, air supply, and setup – all seemed fine. But from a photo they sent, we noticed the suction port had been narrowed.

Although the pump has a 15A port, it had been reduced to 9A. We recommended using a φ15 hose, and after the change, the pump began self-priming without issue. The customer was very satisfied and thanked us for the quick resolution.

With high-viscosity fluids, even small piping restrictions can cause issues. We strongly recommend avoiding hoses smaller than the pump’s rated port size.

At H2, we provide thorough post-sales support to ensure proper installation and reliable operation.

Here’s the model supplied for this case: