> Compatible with concentrated sulfuric acid and caustic soda solutions

FRP Chemical Submersible Pump

This corrosion-resistant submersible pump is designed for chemical transfer, and can handle concentrated sulfuric acid and caustic soda. All-resin construction prevents rust and contamination.

> LC Series Chemical Submersible Pump ー Key Features

The LC Series submersible pump is designed for various chemical solutions, including concentrated sulfuric acid, hydrochloric acid, and caustic soda. Being submerged in operation, it saves installation space and enhances safety by containing leaks within the liquid.

A wide range of options is available. Here are some examples.

Power cable extension

- Length can be specified in 1m units.

- Material: ETFE option available.

Various Voltage Configurations

- Supports various voltages such as 380V, 400V, and 440V.

- Non-applicability certificates for export can also be issued.

Automatic Alternating Control Panel

- Automatic alternating operation linked with level sensors.

- Available for both outdoor and indoor use.

Catalog Download & Inquiries

LC Series Chemical Heat-Resistant Submersible Pump ー Specifications & Lineup

Main Applications:

・Transfer of wastewater containing chemicals

・Transfer of concentrated chemicals from chemical tanks

Corrosion Resistance Specification

| Hydrochloric Acid | Chromic Acid | Acetic Acid | Oxalic Acid | Nitric Acid | Hydrofluoric acid | Phosphoric acid | Sulfuric acid | Aqueous ammonia | Caustic soda | Hydrogen peroxide | Hypochlorous acid | |

| N model | △ | × | 〇 | 〇 | × | × | △ | △ | 〇 | × | × | × |

| S model | 〇 | △ | 〇 | 〇 | 〇 | × | 〇 | 〇 | △ | × | × | △ |

| F model (For Hydrofluoric Acid) | 〇 | △ | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | △ | 〇 | × | △ |

| F model (For Chromic Acid) | 〇 | 〇 | 〇 | 〇 | 〇 | × | 〇 | 〇 | × | × | 〇 | △ |

| LCQ (Main Material: PP) | 〇 | △ | × | 〇 | 〇 | △ | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 |

◯:Suitable △:Limited use ×: Not suitable

※This corrosion resistance chart is compiled based on sales records and material manufacturer data.

Please note that for chemical substances, conditions such as concentration, temperature, and viscosity may affect suitability. Use this chart as a reference for pump selection.

Lineup

| Model | Power Supply Specifications | Total Head – Discharge Flow | Fluid Temperature | Discharge Bore (mm) | Dimensions (W×D×H) | Weight(Kg) |

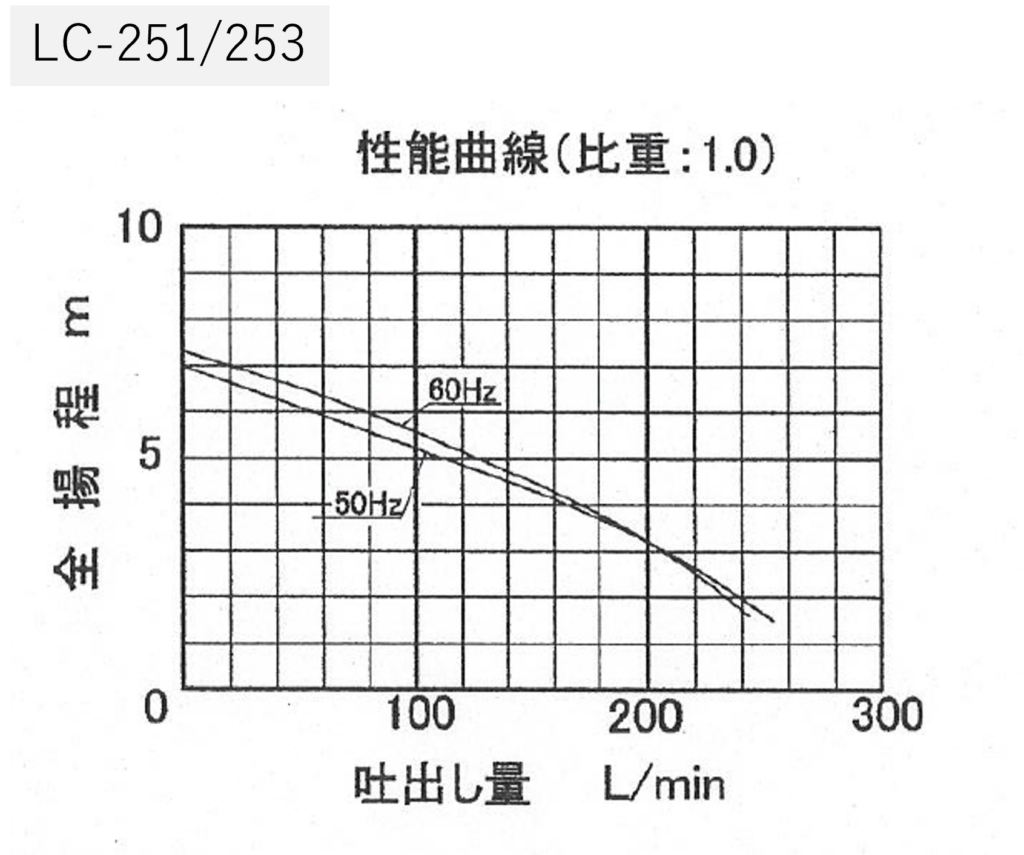

| LC-251 | 100V Single-phase 0.25Kw | 5.0m-120L/min | 35℃ | 40 | 315×220×380 | 11.5 |

| LC-253 | 200V Three-phase 0.25Kw | 5.0m-120L/min | 40℃ | 40 | 315×220×380 | 11.5 |

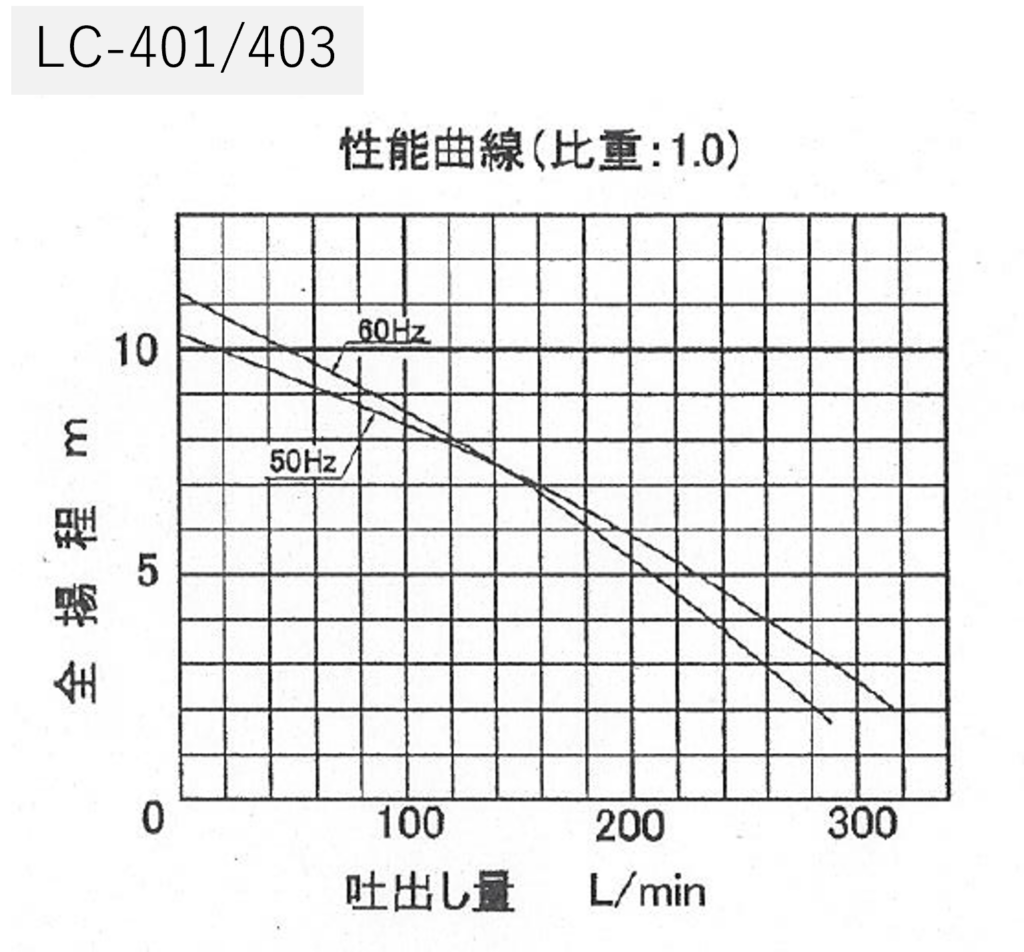

| LC-401 | 100V Single-phase 0.4Kw | 7.0m-150L/min | 35℃ | 50 | 315×220×400 | 14.8 |

| LC-403 | 200V Three-phase 0.4Kw | 7.0m-150L/min | 40℃ | 50 | 315×220×440 | 14.8 |

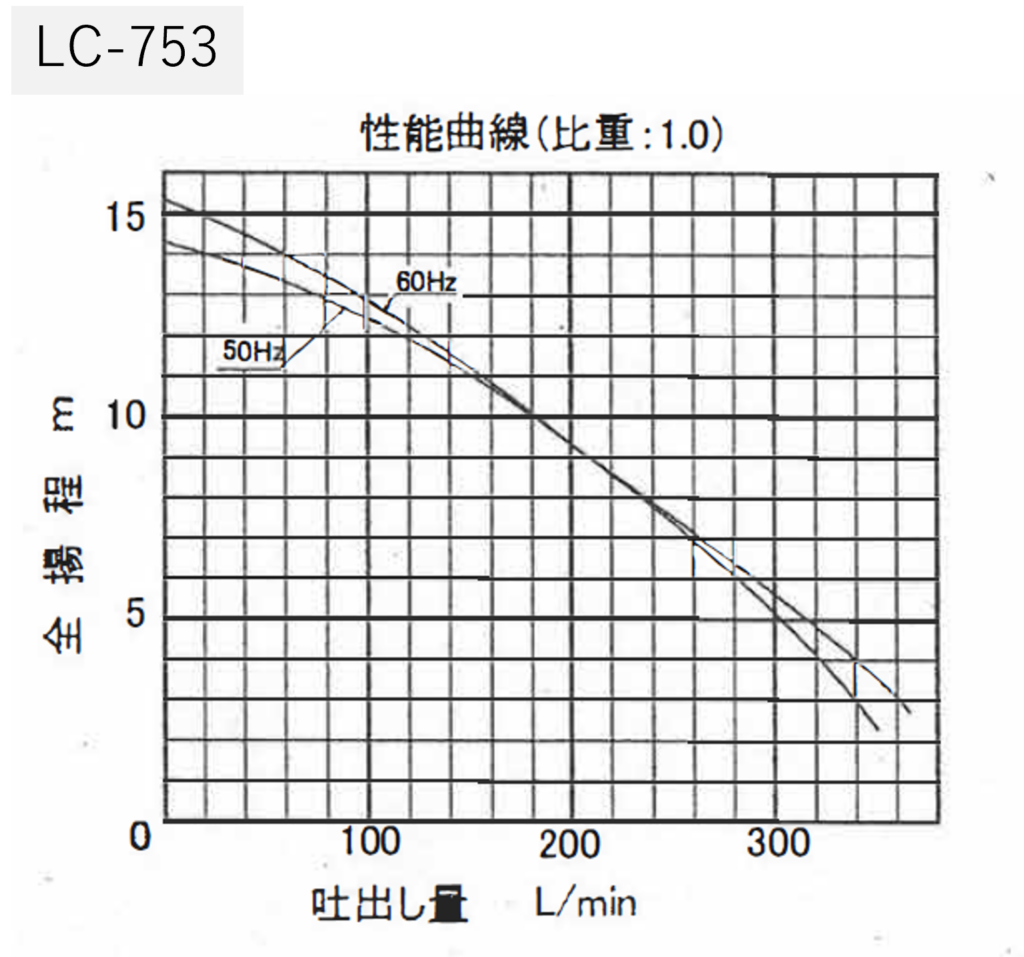

| LC-753 | 200V Three-phase 0.75Kw | 9.0m-210L/min | 40℃ | 50 | 315×220×440 | 15.2 |

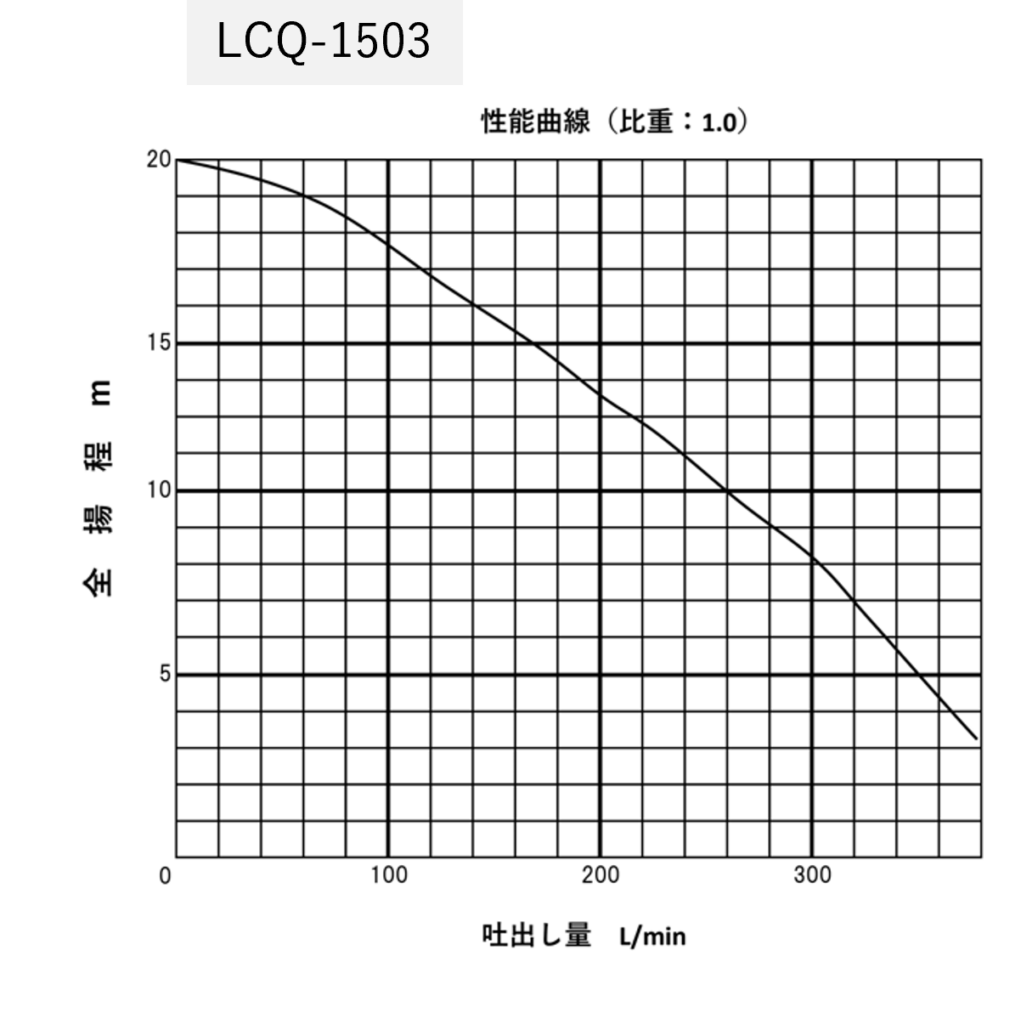

| LCQ-1503 | 200V Three-phase 1.5Kw | 15m-170L/min | 40℃ | 50φ/40 | 175×175×520 | 16.0 |

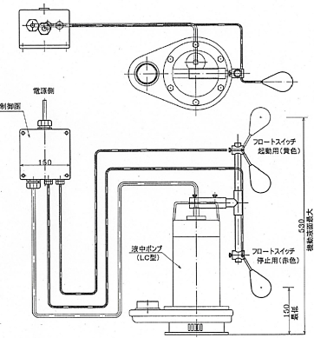

Liquid Level Gauge Specifications

Automatic pump ON-OFF control is easily achieved with a dedicated float and control box. For LC series only.

Performance Curve Diagram

Click the image below to zoom in.

Standard Accessories

・Rope・・・1 piece (LC only)

・Instruction guide (QR code) ・・・・・・・1 sheet

LC Series Chemical Submersible Pumps | Delivery Case Studies

Frequently Asked Questions (FAQs)

- Is power cable extension available?

-

Yes, it is available as an option. You can specify the extension length in 1-meter increments.

- Is repair service available?

-

Yes, we offer repair services. Please send the unit to us, and we will provide a quotation.

- Are there any charges if I choose not to proceed with the repair?

-

No charges will be incurred if no repair is carried out. There will be no disposal or inspection fees either.

- What is the delivery time?

-

The standard lead time for the LC Series chemical submersible pump is approximately 1 to 1.5 months.

Expedited delivery is also possible.

- Is there an explosion-proof version of the chemical submersible pump?

-

We’re sorry, an explosion-proof version is not available for chemical submersible pumps.

- Can corrosion resistance be selected for mixed liquids?

-

For mixed chemicals, please consult us for recommendations.